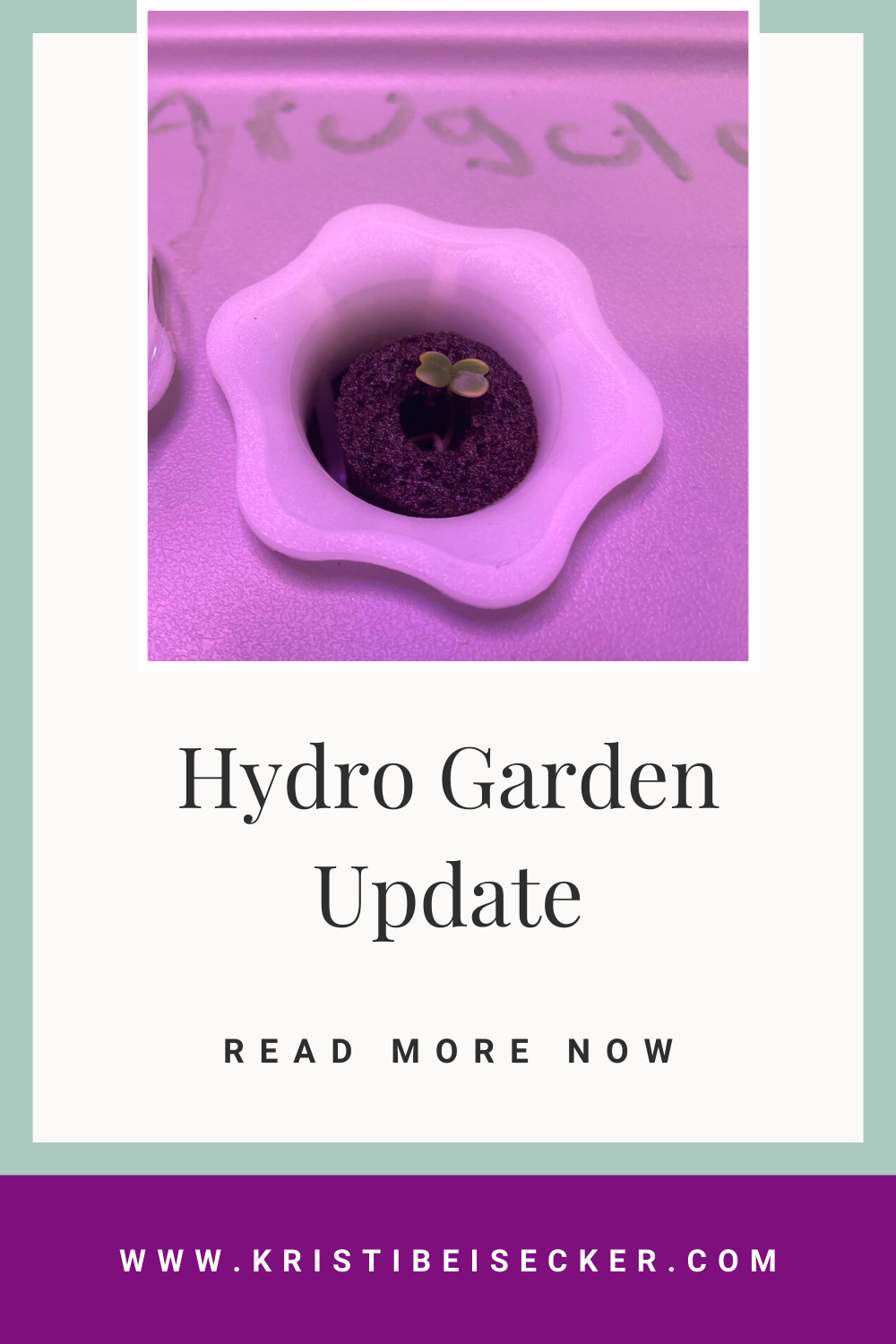

Below are updates to my hydro garden after 5 days. The arugula and kale sprouted through the sponge.

Below are updates to my hydro garden after 5 days. The arugula and kale sprouted through the sponge.

This is a tutorial for my larger hydroponic setup. The setup allows 18 holes for plants; this particular setup has 5 different varieties of greens: arugula, kale mix, cilantro, spinach and green onion.

This is a very simple project however requires basic understanding of hydroponics. The ph level in water is important as it helps imitate the environment of soil-based gardening. The liquid nutrients imitates the nutrients in the soil. You can lower ph levels naturally using lemon or lime juice. The plastic of the tote is important as well make sure it’s food grade; p5 is fine.

Instructions

So using the process above one can make their very own cotton candy machine.

I then thought perhaps a dollar store handheld fan would be a perfect motor:

Take off the blades of the fan and then take an aluminum can and poke holes into it using an awl, or a drill if its something thicker. It doesn’t need to be thicker.

Find a plastic bowl that you can use as a container to catch the spun sugar. Most manufactured machines come with a heater, but for DIY machines you don’t have to have a heater, just have the apparatus by a stove and melt your sugar in a bowl on the stove and then pour it into the holey container.

Attach the fan holder to a piece of cardboard and test your apparatus!

Oh what glorious centrifugal force brings us! 😀

PS: If you buy tonic water and add a little bit of it to the melted sugary mess you might be able to get glowing cotton candy. Tonic water has quinine in it which glows under a black light.

(I hope my mom has her black light bulb still)

Why do I sense that I may need to do this for a package design project in the near future? 😛

Gotta make sure to get paint thinner before I go back to school.

Tutorial: http://mademoisellechaos.blogspot.com/2010/04/how-to-transfer-bw-picture-onto-almost.html

Easy Homemade clay, all you need is newspaper and wallpaper paste.

This is the easiest and cheapest recipe for paper clay.

Steps:

1. Get your newspaper

2. Soak it in water.

3. Tear it into strips. Into a bucket

4. Put more water in it so it just barely covers the paper.

5. Stir it up using a dremmel tool blender, food processor or regular blender.

6. Blend it into a pulp

7. Transfer some pulp into another bucket. Poor more water into the 1st bucket and stir more.

8. Get a cotton (or mesh) bag and put pulp in it and strain it.

9. Take strained pulp and put into the 2nd bucket.

10. Take some wallpaper paste and sprinkle it onto pulp.

11. Stomp/Kneed pulp into a clay.

This technique has been the only technique that uses very little glue.

According to www.wallpaperinstaller.com Cellulose is common binder for a substitute for natural gums and a stabilizer in emulsions as well as a thickening agent. It can be simply created using NaOH (Sodium hydroxide) which dissolves the wood or cotton with an alkali.

Cellulose

“Cellulose methyl ether, produced by treating cellulose from wood or cotton with an alkali, such as sodium hydroxide, followed by methyl chloride. The resulting product is a white granular solid, soluble in cold water but insoluble in hot water. In addition to being used as an adhesive, it is used as a thickening agent, as a substitute for natural gums, and as a stabilizer in emulsions.”

-from Bookbinding and the Conservation of Books Dictionary from the Conservation On-Line (COOL) website“Methyl cellulose occurs as practically odorless and tasteless, white to yellowish-white granules or powder. The pH of a 1% w/v solution is in the range of 5.5 to 8.0. Its angle of repose is about 40 degrees to 50 degrees and it is hygroscopic. It swells and disperses slowly in cold water to form a clear-to-opalescent, viscous, colloidal dispersion. The viscosity is increased with increased concentrations. The viscosity decreases with increased temperatures to about 50 degrees to 60 degrees Celsius, where gel formation occurs. The thermogelation is reversible when the viscous solution reforms upon cooling.”

-from Wade A., Weller P.J. (eds) Handbook of Pharmaceutical Compounding.In paperhanging, cellulose has the highest water content of any paste in general use (around 97%). It usually comes in a small box and is packaged as a white powder. It is mixed with cold water on the job and can be used with a variety of lightweight materials such as porous papers, grasscloth and silk. It’s adhesion is mostly of the mechanical type. It leaves very little solids behind and is not suitable for many wallcoverings which require greater amounts of initial tack and holding power.

What does it take to transform a pile of old T-shirts into spectacular works of woven art? Just a spare hula hoop or embroidery hoop and the techniques we’ll show you here. The oversize looms and easy-to-use loops of T-shirt fabric make these projects particularly appealing to beginning weavers. Learn the basic hoop weaving technique by crafting a colorful accent rug to brighten up a room. And if you want to take the weaving a little further, check out our basket and chair pad weaves

Before you begin, some terms you need to know: the warp is the material you string on the hoop, the weft is the material you weave with.

Source: http://familyfun.go.com/crafts/hula-hoop-rug-995304/print/

source: http://makethebestofthings.blogspot.com/2010/05/crackle-finish-with-elmers-glue.html

I want to use the above finish. I’m thinking about making furniture out of paper pulp. I can’t help but imagine it would have an interesting effect since paper is made from trees.

Here is a “video” of how it is done:

Source: Debbie Wijskamp

Although I think I would have to seal it some how after to keep it from warping.

If I get the furniture looking great out of paper pulp, the next thing I’d like to try is to make a boat of it. Since we’re getting a beach house and all, it’ll be fun to see if I can pull it off.

Source: http://laurathoughts81.blogspot.com/2011/03/make-up-magnet-board.html

I found my weekend project!